Machining – Part of our sheet metal processing

Professional sheet metal processing involves more than just cutting and bending. With our machining services, we take care of the mechanical processing of sheet metal and steel components – precisely according to your specifications. Whether drilling, countersinking, milling, thread cutting, or profile rolling – our skilled professionals carry out all common machining steps efficiently. Our capabilities also include bevelling sheets for weld seam preparation, as well as sheet welding using TIG, MIG, or MAG processes.

Our equipment for machining

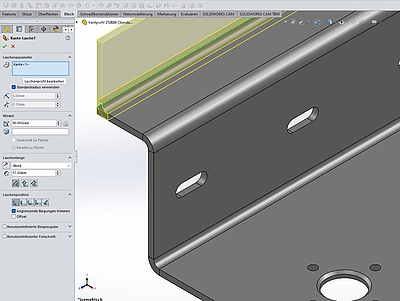

Our machine shop is designed for large workpieces and deep manufacturing capabilities. In machining, we rely on modern technology and skilled craftsmanship:

✔︎ Machining centers for drilling, milling, and thread cutting

✔︎ Edge milling cutters and welding edge formers for sheet beveling

✔︎ TIG, MIG, and MAG welding equipment for sheet welding

✔︎ Mobile devices for cutting, drilling, and grinding

✔︎ In-house paint shop

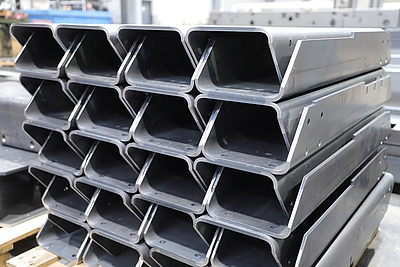

This enables us to provide precise and cost-effective solutions – even for complex requirements or large series production.

Machining as part of the full-service process

Machining is an integral part of our process chain: From the initial cutting and bending to the final weld seam, we deliver ready-to-assemble components. Seamlessly coordinated processes ensure smooth workflows throughout. Upon request, we also take care of additional steps such as galvanizing, coating and blasting.

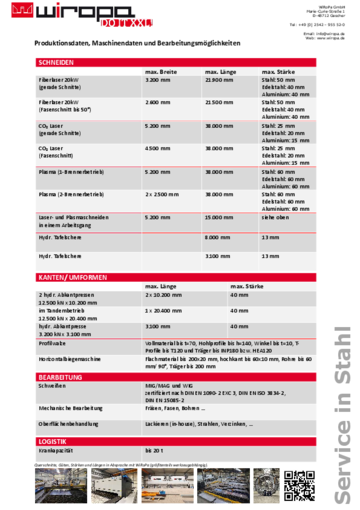

Learn more about the full range of sheet metal processing options we offer in our PDF “Processing Capabilities” – it includes all technical data on material thicknesses and component sizes we handle. If you have any questions or would like personal advice, we’ll be happy to assist you.