Cutting, Bending, Processing – All Under One Roof

Our sheet metal processing is designed for exceptional dimensions. We cut, form and process steel sheets using state-of-the-art machinery and years of experience – with precision, efficiency, and flexibility. Whether you need laser cutting, heavy-duty bending, or mechanical finishing of complex components – we offer everything from a single source.

Cutting – Precise And Versatile

In the field of sheet metal processing, we offer three powerful cutting methods for perfect results: Laser cutting for maximum precision – with material thicknesses up to 50 mm –, plasma cutting for heavy-duty sheets up to 60 mm (also in parallel mode with two torches), and shearing for straight cuts up to 13 mm. Our cutting technology covers a wide range of applications – economical, efficient, and designed for XXL formats.

Powerful Cutting Technology – With Three Methods

We offer you three precise and high-performance methods for sheet metal cutting – each tailored to material, sheet thickness, and quantity. Whether you need maximum precision, large material thicknesses, or simple and cost-effective cuts: with laser, plasma or shearing, we’ll find the right solution for your project. Technical details such as maximum cutting widths, lengths, and material thicknesses can be found on the corresponding subpages. If you have any questions, we are happy to help.

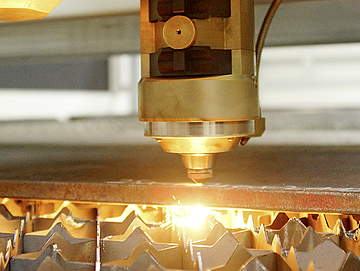

Laser Cutting

Maximum precision for fine cuts: With laser cutting, we process sheet metal with smooth, low-burr edges – precise, fast, and with no need for reworking. Ideal for thin to medium sheet thicknesses, including bevel cuts.

Plasma Cutting

Efficient for high thicknesses: Plasma cutting is the economical solution for thick materials and high throughput. Especially suitable for steel up to 60 mm – robust, fast, and reliable in serial production.

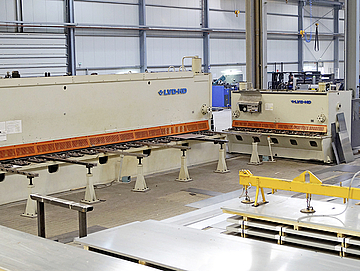

Shearing

Classical strength for straight cuts: With our guillotine shears, we ensure clean cuts with minimal material stress for thicknesses up to 13 mm. Especially suitable for straight cuts in large formats – simple and efficient.

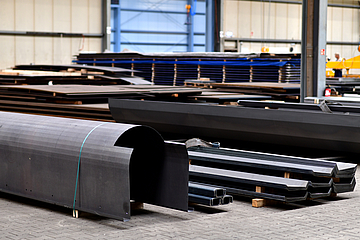

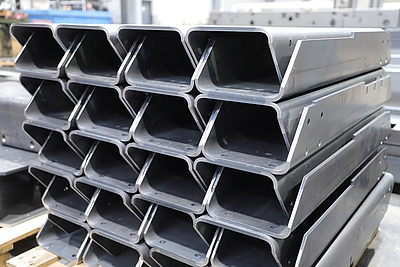

Bending – Sheet Metal Forming with Precision and Power

With our tandem press brakes, we form sheet metal over 20 meters in length – without any welded seams. Whether simple bent parts or technically demanding profiles for crane construction, traffic engineering, or other industrial sectors: our machines bend sheet metal up to 40 mm thickness with a pressing force of up to 2,500 t. Benefit from our experience in bending large-format sheets.

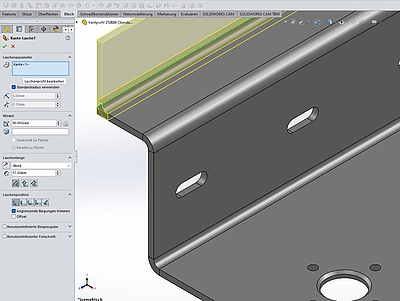

Machining – For Perfect Components

After cutting, we focus on precision down to the last detail: drilling, milling, countersinking, thread cutting, or weld seam preparation – with machining we bring sheet metal into its final shape. Using modern machining centers and extensive expertise, we prepare components ready for assembly – quickly, accurately, and with full documentation. Special surface treatments (e.g. galvanizing, blasting, painting) are also possible.