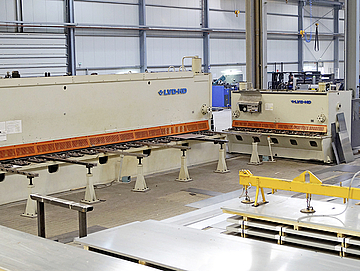

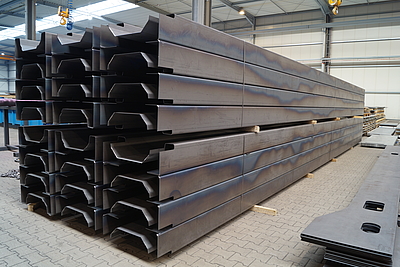

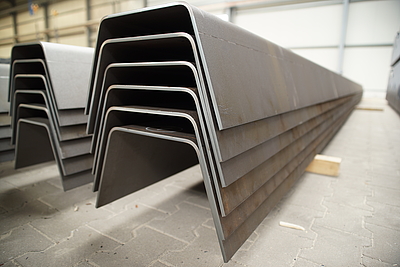

Bending large sheets precisely – with power and control

Experience, machine performance and thoroughness are what count when bending large sheets. We bend sheets up to 20.4 m in length and 40 mm in thickness – with press forces of up to 2,500 t. Whether you need single parts, series components or custom profiles to exact specifications: We provide accurate bending angles, consistent quality, and reliable results – even with difficult geometries or exceptionally long workpieces.

Custom sheet metal bending – directly from our warehouse

With over 3,000 tons of raw material in various dimensions and grades, we offer maximum flexibility. We can bend sheets to your exact specifications at short notice – precisely as required. This enables us to create tailor-made solutions for a wide range of industries – from mechanical engineering to infrastructure, including documentation or machining if requested.

You want to provide your own material? That's no problem either: we can edge according to your specifications - even on a contract basis.

Our equipment for sheet metal bending

This equipment enables cost-efficient bending of complex profiles – as single parts or in series.

✔︎ Tandem press brakes with up to 2,500 t of press force

✔︎ Bending length up to 20,400 mm

✔︎ Material thickness up to 40 mm (depending on material)

✔︎ Bending tools for custom profiles and series production

✔︎ Bending aids and 3D bending simulation

✔︎ Process monitoring for high repeat accuracy

More details about our processing capabilities can be found in the technical datasheets in our download area.

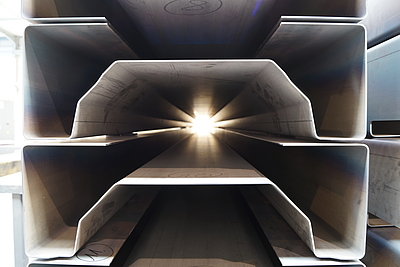

Our press brakes in detail

Our bending technology is designed for large dimensions.

Whether single part or series – we bend with precision, power, and repeatable accuracy.

Press brake 10.20 m

1,250 t press force

2 units

Press brake 3.0 m

320 t press force

1 unit

Press brake 20.40 m

2,500 t press force (tandem)

1 unit

Horizontal bending machine 0.3 m

30 t press force

Profile roller

For profiles up to 120 x 120 mm

Bending as part of our full-service

As a full-service provider, bending for us is often part of a continuous process chain – for example, in the production of drums, reels or steel assemblies. In combination with our cutting and machining services, we create components tailored exactly to your needs.

You can find out more about the extensive possibilities we offer in our PDF “Processing Capabilities”: It includes all technical data, press lengths, bending angles, and sheet thicknesses we process. If you have any questions or would like personal advice, we’re happy to assist you.

Powerful Cutting Technology – With Three Methods

We offer you three precise and high-performance methods for sheet metal cutting – each tailored to material, sheet thickness, and quantity. Whether you need maximum precision, large material thicknesses, or simple and cost-effective cuts: with laser, plasma or shearing, we’ll find the right solution for your project. Technical details such as maximum cutting widths, lengths, and material thicknesses can be found on the corresponding subpages. If you have any questions, we are happy to help.

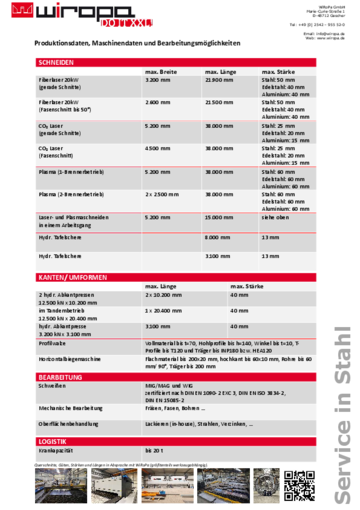

Laser Cutting

Maximum precision for fine cuts: With laser cutting, we process sheet metal with smooth, low-burr edges – precise, fast, and with no need for reworking. Ideal for thin to medium sheet thicknesses, including bevel cuts.

Plasma Cutting

Efficient for high thicknesses: Plasma cutting is the economical solution for thick materials and high throughput. Especially suitable for steel up to 60 mm – robust, fast, and reliable in serial production.

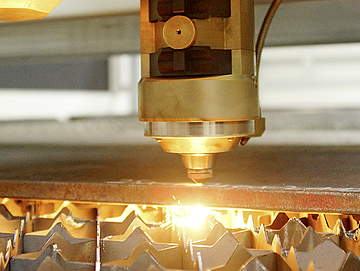

Shearing

Classical strength for straight cuts: With our guillotine shears, we ensure clean cuts with minimal material stress for thicknesses up to 13 mm. Especially suitable for straight cuts in large formats – simple and efficient.