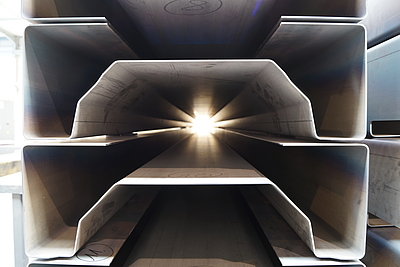

Our laser cutting equipment

WiRoPa has the right solution for anyone who wants to laser cut sheet metal and is looking for precision, dimensional accuracy and process reliability: our state-of-the-art laser production facility combines laser cutting of sheet metal with high dynamics and flexible format sizes for sheet metal cuts in XXL formats. On request, we can also carry out laser marking on sheet metal - e.g. for component marking or documentation.

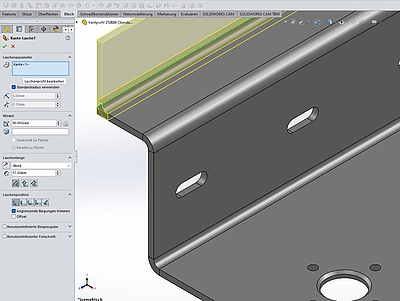

Design – Everything from a single source

Our engineers, technicians and construction mechanics transform your sketches into reliable 3D models and production drawings. CAD-supported designs and structural calculations are naturally part of the process. This is how we create precise metal constructions and XXL components - with maximum flexibility and just in time.

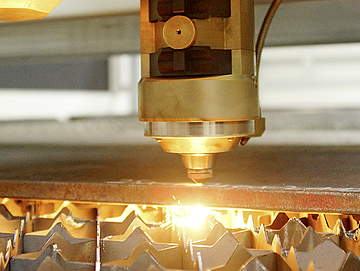

Our laser cutting machines in detail

Laser Cutting Machine 5 kW

Length: 38 m

Width (straight cut): 5.2 m

Width (bevel cut): 4.5 m

Material thickness capacity:

Steel: up to 25 mm

Stainless steel: up to 20 mm

Aluminium: up to 15 mm

Laser Cutting Machine 6 kW

Length: 12.5 m

Width (straight cut): 3 m

Material thickness capacity:

Steel: up to 25 mm

Stainless steel: up to 20 mm

Aluminium: up to 15 mm

Fiber Laser 20 kW

Length: 21.9 m

Width (straight cut): 3.2 m

Width (bevel cut): 2.6 m (up to 50°)

Material thickness capacity:

Steel: up to 50 mm

Stainless steel: up to 40 mm

Aluminium: up to 40 mm

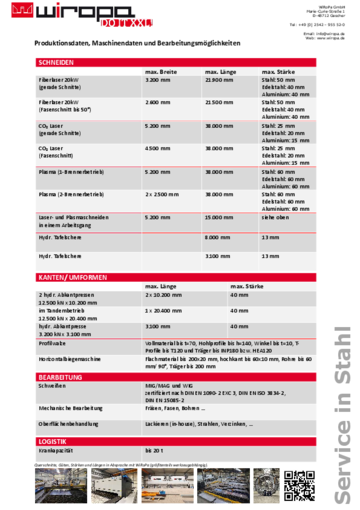

Technical comparison table: Cutting methods

Our three cutting methods each offer specific advantages – from highly precise laser cuts to efficient separation of thick sheets with plasma, or fast, straight cuts using a guillotine shear. In our overview, you’ll find all cutting data for width, length, and material thicknesses for laser, plasma, and shear cutting – clearly presented to support your planning or project preparation. You’ll also find production data, machine specifications, and further processing options.

If you have any questions, you’ll find more details about our processing capabilities on our download page under Processing Capabilities – or simply reach out to us directly. We’re happy to support you with advice and expertise.

Need design assistance for your cutting layouts? Visit our Design section to learn more about our capabilities in CAD, structural analysis, and feasibility assessment.

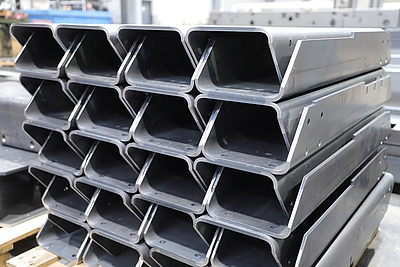

Powerful Cutting Technology – With Three Methods

We offer you three precise and high-performance methods for sheet metal cutting – each tailored to material, sheet thickness, and quantity. Whether you need maximum precision, large material thicknesses, or simple and cost-effective cuts: with laser, plasma or shearing, we’ll find the right solution for your project. Technical details such as maximum cutting widths, lengths, and material thicknesses can be found on the corresponding subpages. If you have any questions, we are happy to help.

Laser Cutting

Maximum precision for fine cuts: With laser cutting, we process sheet metal with smooth, low-burr edges – precise, fast, and with no need for reworking. Ideal for thin to medium sheet thicknesses, including bevel cuts.

Plasma Cutting

Efficient for high thicknesses: Plasma cutting is the economical solution for thick materials and high throughput. Especially suitable for steel up to 60 mm – robust, fast, and reliable in serial production.

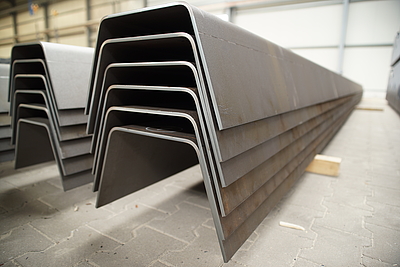

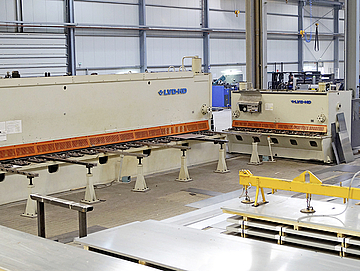

Shearing

Classical strength for straight cuts: With our guillotine shears, we ensure clean cuts with minimal material stress for thicknesses up to 13 mm. Especially suitable for straight cuts in large formats – simple and efficient.